Introduction

Calcium chloride (CaCl₂) is one of the most widely used concrete additives, particularly in cold-weather construction. It accelerates curing, prevents freezing and enhances early strength development. However, improper use can lead to structural risks, including corrosion and durability issues.

This comprehensive guide explores:

- The chemical mechanism behind calcium chloride’s accelerating effects

- Optimal dosage for different temperatures and mix designs

- Critical risks (corrosion, alkali-silica reaction) and mitigation strategies

- Industry standards (ASTM, JGJ/T) for safe application

1. How Calcium Chloride Works: The Science Behind Acceleration

1.1 Hydration Reaction & Temperature Influence

Concrete curing relies on the hydration of cement particles (C₃S, C₂S). Calcium chloride acts as a catalyst, speeding up this process by:

- Increasing ion concentration in the mix promotes faster dissolution of silicates.

- Generating heat through exothermic reactions is crucial in cold weather.

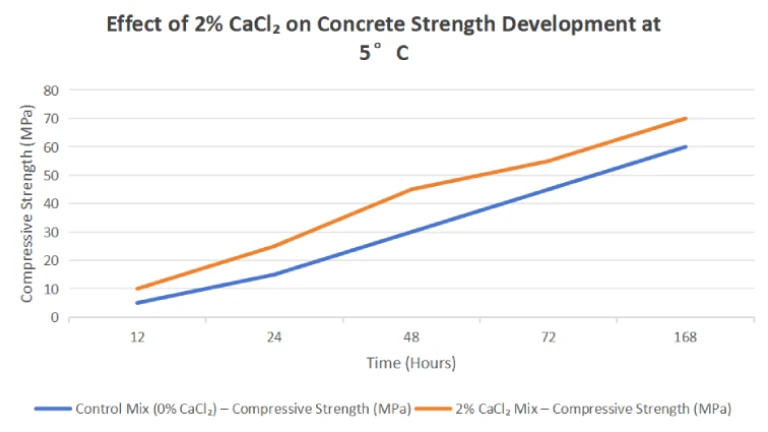

A time-temperature curve (Fig. 1) shows that with 2% CaCl₂, concrete reaches 50% strength 20–30% faster than untreated mixes.

Fig. 1: Strength Development with/without CaCl₂

(Hypothetical data: 2% CaCl₂ reduces setting time by 40% at 5°C.)

1.2 Impact on Microstructure

While CaCl₂ accelerates early strength, excessive use (beyond 2% by cement weight) can:

- Increase porosity due to rapid water consumption.

- Cause shrinkage cracks if drying occurs before full hydration.

2. Engineering Formulations: Dosage, Compatibility & Best Practices

2.1 Recommended Dosage for Cold Weather (-10°C to 5°C)

The optimal CaCl₂ dosage depends on ambient temperature:

| Temperature Range | CaCl₂ (% of Cement Weight) | Expected Strength Gain |

|---|---|---|

| 5°C to 10°C | 1–1.5% | 30–40% at 24 hours |

| -5°C to 5°C | 1.5–2% | 50–60% at 48 hours |

| Below -5°C | 2% + anti-freeze agents (e.g., nitrites) | Prevents freezing, but requires insulation. |

Note: Dosages above 2% are not recommended due to corrosion risks.

2.2 Synergy with Accelerators (Non-Chloride vs. Chloride-Based)

Calcium chloride is often combined with:

- Triethanolamine (TEA): Enhances early strength without increasing corrosion risk.

- Calcium Nitrite: Provides freeze protection while inhibiting rust.

Avoid mixing with:

- Sulfate-based accelerators (e.g., sodium thiocyanate) → Can cause delayed ettringite formation (DEF).

3. Critical Risks & Mitigation Strategies

3.1 Corrosion of Reinforcement Steel

Chlorides depassivate the protective oxide layer on the rebar, leading to electrochemical corrosion.

Prevention methods:

- Epoxy-coated rebar or stainless steel reinforcement.

- Cathodic protection (sacrificial anodes or impressed current).

- Corrosion inhibitors (e.g., calcium nitrite at 10–15% by cement weight).

3.2 Why Prestressed Concrete Bans CaCl₂

Prestressed concrete is highly susceptible to chloride-induced stress corrosion cracking (SCC). ASTM A416 prohibits CaCl₂ in:

- Post-tensioned beams

- Pre-tensioned railway sleepers

3.3 Alkali-Silica Reaction (ASR) Risk

CaCl₂ can exacerbate ASR in reactive aggregates. Mitigation includes:

- Using low-alkali cement (<0.6% Na₂O equivalent).

- Adding pozzolans (fly ash, slag) to reduce permeability.

4. Compliance with Industry Standards

4.1 ASTM D98 vs. JGJ/T 104: Key Differences

| Parameter | ASTM D98 (US) | JGJ/T 104 (China) |

|---|---|---|

| Max Chloride Content | 1% for reinforced concrete | 0.1% for humid environments |

| Testing Method | Potentiometric titration | Volumetric analysis |

| Pre-stressed Ban | Absolute prohibition | Case-by-case evaluation |

Practical Tip: For marine environments, EN 206 (EU) limits chlorides to 0.4% for reinforced concrete.

Conclusion

Calcium chloride remains a cost-effective accelerator for cold-weather concreting, but its risks demand strict adherence to:

✔ Dosage limits (1–2% by weight)

✔ Corrosion prevention (inhibitors, coatings)

✔ Material compatibility (avoid sulfates, prestressed applications)

For critical projects, consider non-chloride alternatives (e.g., calcium formate).