Oxidation is one of the most critical challenges in beer production, affecting flavor, aroma, color, and shelf life. Even small amounts of oxygen can trigger reactions that compromise quality. To mitigate these risks, breweries often rely on sodium metabisulfite (Na₂S₂O₅), a widely used antioxidant and preservative in the beverage industry.

Understanding Oxidation in Beer

Oxidation occurs when oxygen interacts with beer components such as malt sugars, phenolic compounds, and hop-derived iso-alpha acids. This reaction can lead to:

- Off-flavors: Beer may develop stale, cardboard-like, or sherry-like notes over time.

- Aroma deterioration: Volatile hop aroma compounds are especially susceptible to oxidative loss.

- Color changes: Light-colored beers can darken prematurely.

- Shortened shelf life: Oxidized beers tend to spoil faster, affecting marketability.

Factors that increase oxidation risk include prolonged fermentation, excessive aeration during transfer, poor packaging, and storage at high temperatures. Understanding these factors is crucial for effective prevention.

Role of Sodium Metabisulfite

Sodium metabisulfite acts as a potent antioxidant and mild antimicrobial agent, providing multiple benefits in beer production:

- Scavenging Oxygen: It chemically reacts with dissolved oxygen in beer, preventing oxidative reactions that generate off-flavors.

- Preserving Sensitive Compounds: Hop bitterness (iso-alpha acids) and delicate malt aromas are protected from degradation.

- Enhancing Stability: By limiting oxidation, industrial grade sodium metabisulfite helps maintain consistent flavor, color, and aroma over the product’s shelf life.

- Antimicrobial Protection: It can inhibit growth of certain spoilage yeasts and bacteria, further improving quality.

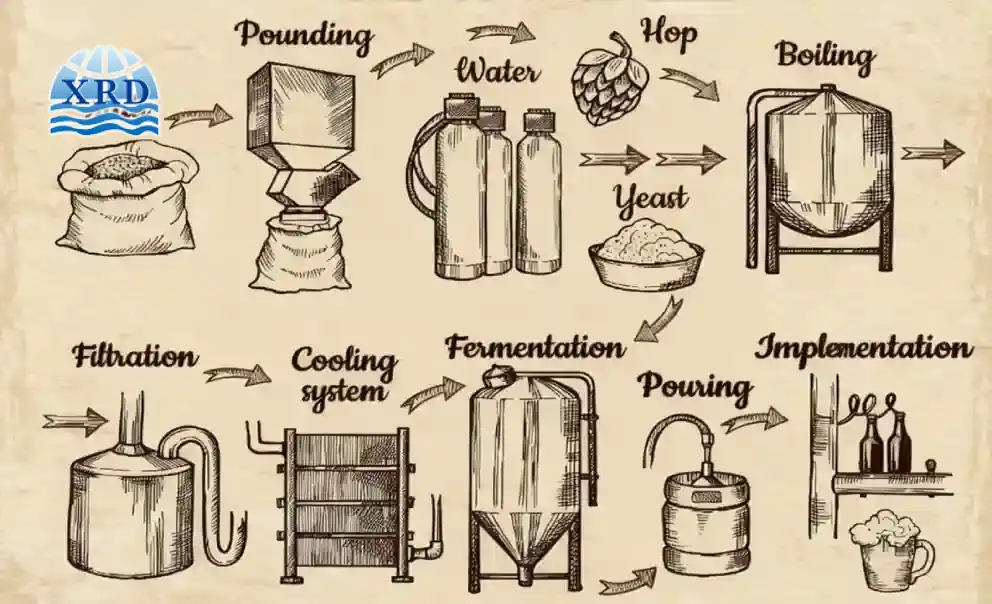

Application in the Brewing Process

Breweries incorporate sodium metabisulfite at critical points:

- Post-Fermentation: A controlled dose is added after primary fermentation to protect beer during racking, blending, and maturation.

- During Packaging: Small amounts are sometimes introduced during bottling or kegging to minimize oxygen exposure during filling.

- Cleaning and Sanitization: Sodium metabisulfite solutions are used for sanitizing tanks and pipelines, preventing microbial growth and oxidative reactions.

- Combination with Inert Gases: Breweries often combine sulfites with nitrogen or carbon dioxide flushing to further reduce dissolved oxygen in beer.

Note: Dosage must be carefully controlled. Excess sulfites can impart a noticeable taste or exceed regulatory limits, especially in wines or craft beers.

Practical Advantages for Breweries

- Flavor Consistency: Preserves the intended taste profile from production to consumption.

- Extended Shelf Life: Slows oxidative deterioration, making beer more marketable for longer periods.

- Cost Efficiency: Small quantities of sodium metabisulfite provide significant protection, suitable for large-scale operations.

- Compatibility with Various Beer Styles: Effective for lagers, ales, stouts, and specialty beers, though dosage may vary by style.

Safety and Regulatory Considerations

Sodium metabisulfite is generally recognized as safe (GRAS) when used appropriately. However, breweries must:

- Follow Local Regulations: Maximum sulfite levels differ by region and product type.

- Label Accordingly: Some consumers are sensitive to sulfites and require clear labeling.

- Monitor Quality: Overuse can lead to detectable sulfur notes, while underuse may fail to prevent oxidation.

Case Study: Craft Breweries vs. Large-Scale Breweries

- Craft Breweries: Typically use minimal additives and rely on oxygen-free packaging. Small doses of sodium metabisulfite may be used selectively to protect delicate hop-forward beers.

- Large-Scale Breweries: Often produce high volumes that undergo long storage and shipping. Sodium metabisulfite is critical for maintaining product consistency across batches and regions.

Conclusion

Sodium metabisulfite plays a vital role in modern brewing by preventing oxidation, preserving flavor and aroma, and extending shelf life. Its controlled use allows breweries—from craft to industrial—to deliver high-quality beer consistently to consumers.