From Vine to Bottle: Why Protection Matters in Winemaking

The journey from vine to bottle is a delicate process in which oxygen exposure and microbial activity can easily compromise wine quality. From grape crushing to long-term aging, even minor chemical imbalances may result in oxidation, off-flavors, or microbial spoilage.

In professional winemaking, Sodium Metabisulfite (Na₂S₂O₅) serves as a primary line of defense. Commonly referred to as sulfites, it is the most widely used source of sulfur dioxide (SO₂)—a compound that functions as both a powerful antioxidant and an antimicrobial agent. When applied correctly, sodium metabisulfite helps preserve freshness, stabilize flavor, and protect the wine’s color and aromatic profile throughout production and storage.

The Essential Roles of Sodium Metabisulfite

Oxidation Prevention and Aroma Preservation

Oxidation is one of the most persistent threats in winemaking. When grape juice or finished wine comes into contact with oxygen, enzymatic and chemical reactions can cause browning and the rapid loss of delicate fruity and floral aromas.

Sodium metabisulfite protects against this process by releasing SO₂, which acts as an oxygen scavenger. It reacts with dissolved oxygen and oxidative byproducts, preventing damage to volatile aroma compounds. This protection of the wine’s nose and palate is essential for maintaining brightness, freshness, and varietal character—even after extended aging.

Microbial Control and Fermentation Stability

Beyond oxidation control, sodium metabisulfite is indispensable for microbial management. Grapes naturally carry wild yeasts, bacteria, and molds that can produce undesirable flavors or convert wine into acetic acid (vinegar).

By adding controlled amounts of sulfites, winemakers suppress spoilage microorganisms while allowing sulfite-tolerant commercial wine yeasts to dominate fermentation. This selective control ensures a clean, predictable fermentation and prevents microbial instability later in the wine’s life.

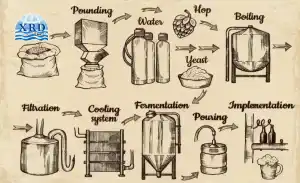

Strategic Timing and Application in Winemaking

The effectiveness of sodium metabisulfite depends heavily on when and how it is applied.

At Crushing:

The first critical addition typically occurs during grape crushing. Sulfites added at this stage inhibit oxidative enzymes such as polyphenol oxidase, protecting juice quality before fermentation begins.

After Fermentation:

Once alcoholic fermentation is complete, a secondary addition is often made to stabilize the wine. This step helps prevent unwanted malolactic fermentation (when not desired) and protects the wine from aerobic bacteria during maturation and aging.

Before Bottling:

A final adjustment is usually applied prior to bottling. This ensures microbial stability, oxidation resistance, and a consistent shelf life once the wine enters distribution.

Recommended Dosage and the Influence of pH

Determining the correct dosage of sodium metabisulfite requires a clear understanding of wine chemistry—especially pH. The antimicrobial effectiveness of SO₂ is strongly pH-dependent.

At lower pH levels (higher acidity), a greater proportion of SO₂ exists in its molecular form, which is the most effective at inhibiting microbial growth. As pH increases, higher sulfite additions are required to achieve the same level of protection.

Typical free SO₂ targets include:

- Dry white wines: 30–40 mg/L

- Red wines: 20–30 mg/L (partially protected by tannins)

- Sweet wines: ≥50 mg/L, due to residual sugars and higher re-fermentation risk

These ranges help balance protection with sensory quality.

Safety, Compliance, and Quality Balance

While sodium metabisulfite is an essential winemaking tool, its use is regulated worldwide. Most regulatory authorities require wines containing more than 10 mg/L of sulfites to display a “Contains Sulfites” label. This transparency protects consumers with sulfite sensitivities, a small but important segment of the population.

For winemakers, the guiding principle is maximum protection with minimum intervention. Insufficient sulfite levels increase the risk of oxidation and spoilage, while excessive dosing can result in sharp, matchstick-like aromas that mask the wine’s natural bouquet.

Conclusion: A Cornerstone of Quality Winemaking

When used judiciously, sodium metabisulfite acts as a protective shield throughout the winemaking process. It allows the flavors developed in the vineyard to remain intact, free from oxidative damage or microbial interference.

Ultimately, the controlled and informed use of sodium metabisulfite is not about altering wine—it is about preserving authenticity, ensuring stability, and delivering a product that reflects its origin, craftsmanship, and intended character.