Calcium chloride is widely used across industries such as deicing, dust control, oil & gas, construction, and chemical processing. One of the most common complaints from buyers and end users is caking—the hardening or lumping of calcium chloride during storage or transport. In most cases, this problem can be traced back to low-quality calcium chloride combined with improper packaging and storage conditions.

This article explains why low-quality calcium chloride cakes easily, the technical factors behind the issue, and practical, proven methods to prevent caking, especially for bulk and export shipments.

What Is Caking in Calcium Chloride?

Caking occurs when calcium chloride particles absorb moisture from the air, partially dissolve, and then recrystallize under pressure or temperature changes. This process causes individual granules or flakes to bond together, forming hard masses that are difficult to break apart.

Caking does not just reduce usability—it can also:

- Increase handling and labor costs

- Cause feeding or spreading equipment blockages

- Create negative perceptions of product quality

- Lead to customer complaints and returns

Why Low-Quality Calcium Chloride Is More Prone to Caking

High Hygroscopicity and Deliquescence

Calcium chloride is naturally hygroscopic, meaning it absorbs moisture from the air. Low-quality products tend to have:

- Higher levels of free calcium chloride fines

- Poorly controlled crystal structure

- Excessive surface area

These factors accelerate moisture uptake, leading to rapid surface wetting and clumping.

Excessive Impurities

Low-grade calcium chloride often contains higher concentrations of impurities such as:

- Magnesium salts

- Sodium chloride

- Sulfates and insoluble residues

These impurities disrupt stable crystal formation and promote uneven moisture absorption, making caking more likely during temperature fluctuations.

Poor Particle Size Distribution

Inconsistent granule or flake sizes are a major contributor to caking. Low-quality production processes often generate:

- Too many fines (powder)

- Irregular-shaped particles

- Weak granules that break during transport

Fine particles absorb moisture faster and act as binding agents between larger particles, accelerating agglomeration.

Insufficient Drying During Manufacturing

If calcium chloride is not properly dried before packaging, residual internal moisture remains trapped within the product. During storage:

- This moisture migrates to the surface

- Dissolution–recrystallization cycles occur

- Hard caked blocks form over time

Low-cost manufacturers may shorten drying time to reduce energy costs, increasing long-term caking risk.

Inadequate Packaging Materials

Low-quality calcium chloride is often packed in:

- Thin woven bags without inner liners

- Non-moisture-barrier bulk bags

- Poorly sealed or reused packaging

Such packaging offers little resistance to humidity, especially during ocean transport or warehouse storage.

How to Prevent Calcium Chloride Caking

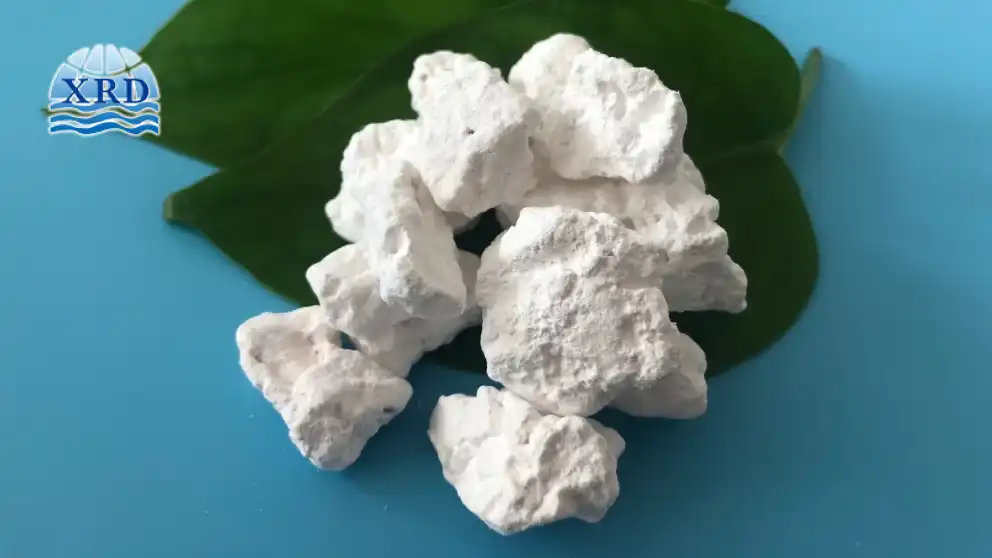

Choose High-Purity Calcium Chloride

Selecting high-purity industrial grade calcium chloride with higher purity (typically ≥ 94% for flakes and pellets) significantly reduces caking risk. High-purity material:

- Has more stable crystal structures

- Contains fewer hygroscopic impurities

- Exhibits better long-term storage behavior

Always request:

- Certificate of Analysis (COA)

- Impurity limits

- Moisture content specifications

Control Particle Size and Shape

Well-manufactured calcium chloride should have:

- Uniform granules or flakes

- Minimal fines

- High mechanical strength

For bulk applications, pelletized or prilled calcium chloride performs better than irregular flakes or powder.

Use Anti-Caking Treatments (When Applicable)

Some industrial grades can benefit from approved anti-caking agents or surface treatments that:

- Reduce surface moisture absorption

- Improve flowability

- Minimize particle bonding

These treatments must be compatible with the intended application, especially for food, pharmaceutical, or environmental uses.

Upgrade Packaging and Moisture Protection

Effective packaging is critical for preventing caking:

- Use PE-lined woven bags or multi-layer kraft bags

- Choose moisture-barrier FIBC bags for bulk shipments

- Ensure proper heat sealing and pallet wrapping

For export shipments, additional measures such as desiccants and container liners can significantly reduce humidity exposure. Professional calcium chloride packaging solutions, such as PE-lined bags, moisture-barrier FIBC bags, and container liners, play a critical role in preventing humidity exposure.

Improve Storage and Handling Conditions

Even high-quality calcium chloride can cake if stored improperly. Best practices include:

- Storing in dry, ventilated warehouses

- Avoiding direct contact with floors and walls

- Minimizing temperature fluctuations

- Using FIFO (First In, First Out) inventory rotation

How to Identify Low-Quality Calcium Chloride Before Buying

Before placing large orders, watch for warning signs such as:

- Excessive powder at the bottom of bags

- Visible moisture or wet patches

- Inconsistent particle size

- Lack of detailed COA or vague specifications

Requesting samples and conducting short-term storage tests under humid conditions can reveal potential caking issues early.

Conclusion

Caking problems in calcium chloride are rarely unavoidable—they are most often the result of low product quality, high impurity levels, poor particle control, and inadequate packaging. While calcium chloride is inherently hygroscopic, high-quality manufacturing and proper handling can dramatically reduce caking risks.

By choosing a reliable calcium chloride supplier, specifying quality parameters clearly, and investing in appropriate packaging and storage solutions, buyers can ensure consistent performance and avoid costly downstream issues.

If you need guidance on selecting non-caking industrial-grade calcium chloride for your specific application, working closely with an experienced manufacturer is the most effective preventive strategy.