With increasingly stringent environmental regulations—such as Class A discharge standards—urban wastewater treatment plants face mounting pressure to maintain stable and compliant effluent quality. Variations in influent composition, seasonal low temperatures, hydraulic shocks, and organic load fluctuations frequently challenge process stability and increase the risk of non-compliance.

Under these conditions, chemical treatment reliability becomes a decisive factor. As a high-performance inorganic polymer flocculant, Polyaluminum Chloride (PAC) has become a critical component in municipal wastewater treatment strategies, helping plants consistently meet regulatory limits for suspended solids (SS), phosphorus, and turbidity.

How PAC Stabilizes Water Quality in Municipal Wastewater Treatment

The effectiveness of Polyaluminum Chloride lies in its advanced hydrolysis behavior and polymeric aluminum species, which outperform traditional aluminum or iron salts.

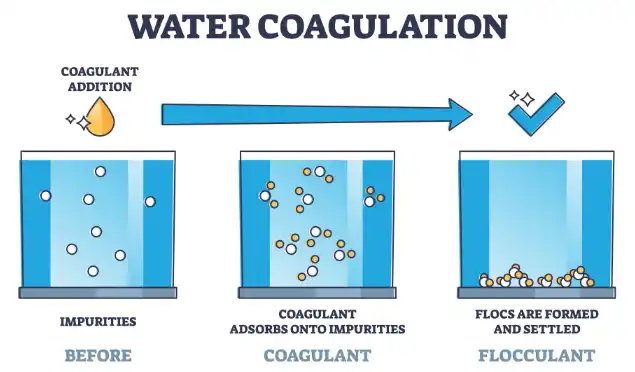

PAC improves treatment stability through several synergistic mechanisms:

- Charge neutralization: PAC rapidly neutralizes negatively charged colloids commonly present in municipal sewage, reducing electrostatic repulsion.

- Adsorption bridging: Polymeric aluminum chains link fine particles together, forming larger and denser flocs.

- Sweep flocculation: Hydrolyzed aluminum hydroxide precipitates enmesh suspended solids, accelerating sedimentation.

- Chemical phosphorus removal: PAC reacts with soluble orthophosphates to form insoluble aluminum phosphate, providing a reliable safeguard when biological phosphorus removal becomes unstable.

Together, these mechanisms ensure consistent effluent clarity and improve total phosphorus (TP) compliance, even under fluctuating operating conditions.

Strategic Application of PAC Across Treatment Stages

To maximize compliance rates, PAC should be strategically deployed at multiple points in the treatment train:

Enhanced Primary Treatment

When dosed at the primary clarification stage, PAC significantly reduces incoming SS and BOD loads, easing the burden on downstream biological processes and improving overall system resilience.

Secondary Clarification and Tertiary Polishing

In secondary or tertiary treatment, PAC functions as a polishing agent, removing residual fine particles and phosphorus prior to final disinfection—critical for meeting low turbidity and TP limits.

Emergency and Shock Load Control

For plants exposed to industrial shock loads, stormwater intrusion, or seasonal inflow variability, PAC provides operational flexibility. Rapid dosage adjustment allows operators to restore effluent stability quickly and prevent permit exceedances.

Operational Optimization: Dosage Control and Product Selection

Compliance success depends not only on using PAC, but on precision dosing and appropriate product selection.

- Dosage optimization: Regular jar testing is essential to identify the optimal dosage window that minimizes turbidity while avoiding excessive chemical sludge production.

- Product specifications: Municipal wastewater applications typically require high-purity PAC with a controlled basicity range (commonly 60%–90%) to ensure predictable hydrolysis and floc formation.

- Cost-performance evaluation: When assessing the polyaluminum chloride unit price, operators should focus on effective Al₂O₃ content, not just cost per ton. Lower-grade PAC often results in higher consumption rates and increased sludge handling expenses, ultimately raising total operating costs.

Choosing a Reliable PAC Manufacturer for Long-Term Compliance

Consistent compliance relies heavily on raw material stability. Partnering with a qualified and experienced PAC manufacturer ensures that every batch meets required quality standards, such as GB 15892-2020 or equivalent international specifications.

A professional supplier provides more than just product delivery. Value-added support typically includes:

- Technical guidance on dosage optimization

- Assistance in addressing seasonal or influent-related challenges

- Stable supply chains that reduce operational risk

By securing a dependable PAC supplier, wastewater treatment plants can better manage influent variability and maintain long-term regulatory performance.

Economic and Environmental Benefits of PAC-Based Treatment

Beyond regulatory compliance, Polyaluminum Chloride delivers measurable economic and environmental advantages:

- Effective performance across a wider pH range

- Lower dosage requirements compared to alum or ferric salts

- Formation of denser, easier-to-dewater sludge

- Reduced chemical consumption and disposal costs

For modern urban wastewater treatment plants, PAC functions as a cost-efficient and reliable risk-mitigation tool, protecting both environmental outcomes and the facility’s regulatory reputation.