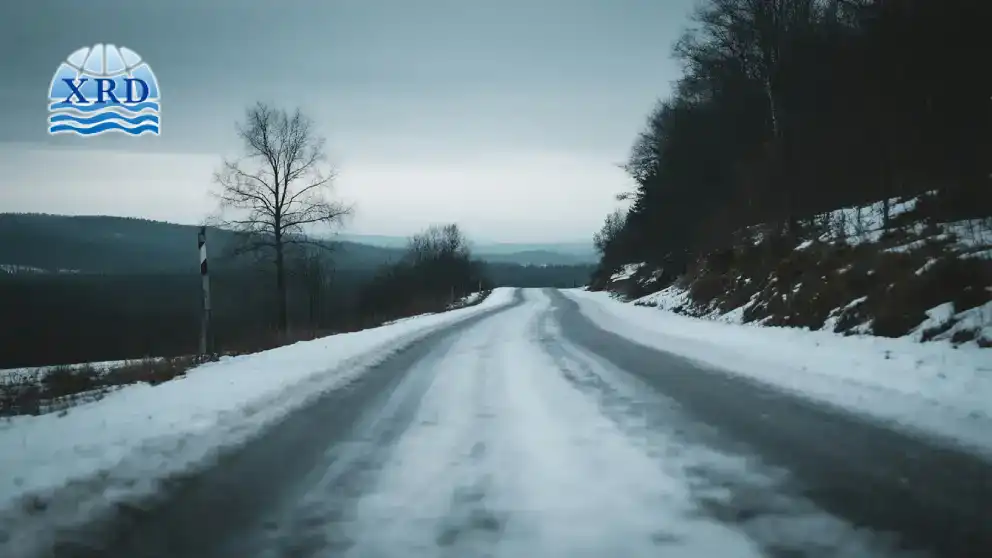

Northern US states face some of the harshest winter road conditions in North America. Prolonged subzero temperatures, frequent snowstorms, and repeated freeze–thaw cycles create constant safety and maintenance challenges. State Departments of Transportation (DOTs) and municipal agencies must balance public safety, operational efficiency, and long-term infrastructure protection. As a result, calcium chloride has become a preferred deicing material for winter road maintenance in cold-climate regions.

Winter Road Maintenance Challenges in Cold-Climate States

In northern states, winter temperatures often fall below the effective range of conventional road salt. Ice bonds strongly to pavement, reducing traction and increasing accident risks for passenger vehicles, commercial fleets, and emergency services. Road maintenance teams must respond quickly while minimizing repeated applications that increase labor costs and equipment wear.

Agencies typically look for deicing solutions that deliver three core benefits:

- Reliable performance in extreme cold

- Rapid ice penetration and melting

- Reduced material usage over long winter seasons

Why Calcium Chloride Performs Better in Extreme Cold

Calcium chloride is highly effective in low-temperature environments because it lowers the freezing point of water more aggressively than sodium-based deicers. When calcium chloride dissolves, it releases heat through an exothermic reaction, accelerating ice break-up and brine formation.

This ability to generate heat on contact allows industrial grade calcium chloride for road deicing to start working immediately, making it particularly valuable during sudden temperature drops, overnight icing, and early-morning road treatment in northern US states.

Calcium Chloride vs Other Deicing Materials

The table below illustrates why calcium chloride is often selected over other common winter road deicing chemicals.

| Deicing Material | Effective Temperature Range | Ice Melting Speed | Typical Application Rate | Performance in Extreme Cold |

|---|---|---|---|---|

| Calcium Chloride | Down to -25°F (-32°C) | Very fast | Low | Excellent |

| Sodium Chloride (Rock Salt) | Above 15°F (-9°C) | Moderate | High | Poor |

| Magnesium Chloride | Down to -5°F (-21°C) | Fast | Medium | Moderate |

Because calcium chloride performs at significantly lower temperatures, many agencies evaluating calcium chloride deicer vs sodium chloride find that calcium-based products deliver more reliable results during severe winter conditions.

Cost Efficiency and Infrastructure Protection

Although calcium chloride may have a higher upfront cost per ton, its overall seasonal cost is often lower. Faster ice melting reduces the need for repeated spreading, which lowers labor, fuel, and equipment operating expenses.

Additionally, calcium chloride helps limit pavement deterioration caused by freeze–thaw cycles. By reducing ice bonding and water penetration into road surfaces, it contributes to longer service life for asphalt, concrete, bridges, and expansion joints—critical factors for state and municipal infrastructure budgets.

Environmental and Operational Advantages

Environmental responsibility is increasingly important in public-sector winter maintenance programs. Because calcium chloride requires lower application rates to achieve effective results, total chloride release into surrounding soil and waterways can be reduced compared with traditional salt-based methods.

From an operational perspective, calcium chloride offers several advantages:

- Compatible with pre-wetting and liquid anti-icing systems

- Hygroscopic properties that help maintain surface moisture and traction

- Reduced material scatter caused by traffic and wind

These characteristics make calcium chloride well suited to modern winter road maintenance operations.

Why State DOTs and Municipalities Choose Calcium Chloride

For northern US states, winter road safety depends on consistent performance, dependable supply, and predictable results. Calcium chloride has a long-established track record in cold regions such as the Upper Midwest and Great Lakes states.

To ensure uninterrupted winter operations, agencies typically work with a reliable calcium chloride manufacturer for road maintenance that can deliver consistent product quality, meet specification requirements, and support large-volume demand. At the same time, partnering with an experienced calcium chloride supplier helps ensure stable logistics and on-time delivery throughout the winter season.